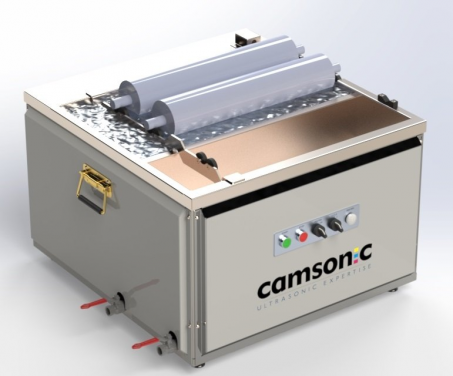

Narrow Web Ultrasonic Anilox Roller Cleaning System Princess

Collection: Anilox Cleaning Machines

Narrow Web Ultrasonic Anilox Roller Cleaning System Princess

Collection: Anilox Cleaning Machines

Available in 3 sizes 4,6 and 8 Roller and each Size will clean Rollers with diameters of up to 165mm

OPTIONS

4 Roller

- Will clean four rollers with face lengths of up to 600mm simultaneously.

- Will clean two sleeves with face lengths of 1300 simultaneously.

6 Roller

- Will clean six rollers with face lengths of up to 600mm simultaneously.

- Will clean three sleeves with face lengths of 1300simultaneously.

8 Roller

- Will clean eight rollers with face lengths of up to 600mm simultaneously.

- Will clean four sleeves with face lengths of 1300 simultaneously.

- All units include a rinse tank as standard.

- Fast and easy to operate with touch screen controls simplifies multi-stage operation to one press of a button.

- Designed to clean your items with minimal input from the operator.

- Frequency sweep circuit which automatically changes the frequency to reduce the chance of any ‘hot spots’ in the liquid that could potentially damage items.

- High-Grade Stainless steel constructionLow consumption of cleaning detergents.

- Bespoke to individual customer requirements.

Specs:

- Micro Computer Controlled Ultrasonic Generators: Provides a fast & gentle cleaning.

- PLC touch screen controls: Easy to operate with clear instructions.

- Frequency sweep circuit: Eliminates ‘hot spots’ in the solution to avoid roller damage.

- 24/7 Heater control: Set the heating to come on whenever you want so the tank is ready when you want.

- Low water level lockout: Stops the machine from overheating when the tank is empty to reduce operator error.

- PLC driven fault-finding diagnostics: Identifies any problems should they arise.

- Bi-direction roller rotation: Provides an even clean with little input from the operator, prevents roller creeping or staying in one position.

- Multi-lingual instruction facility – Touch screen instructions & commands in the language of your choice.

Our tanks offer an outstanding clean for anilox rollers without the need to remove gears or bearings and giving a high level of anilox sealant care.

Applications:

For cleaning laser-engraved ceramic and chrome-plated Anilox rollers and sleeves.Suitable for water-based, solvent-based and UV inks and coatings.

Warranty:

All Camsonic models have a 2-year warranty on all parts.

Available in 3 sizes 4,6 and 8 Roller and each Size will clean Rollers with diameters of up to 165mm

OPTIONS

4 Roller

- Will clean four rollers with face lengths of up to 600mm simultaneously.

- Will clean two sleeves with face lengths of 1300 simultaneously.

6 Roller

- Will clean six rollers with face lengths of up to 600mm simultaneously.

- Will clean three sleeves with face lengths of 1300simultaneously.

8 Roller

- Will clean eight rollers with face lengths of up to 600mm simultaneously.

- Will clean four sleeves with face lengths of 1300 simultaneously.

- All units include a rinse tank as standard.

- Fast and easy to operate with touch screen controls simplifies multi-stage operation to one press of a button.

- Designed to clean your items with minimal input from the operator.

- Frequency sweep circuit which automatically changes the frequency to reduce the chance of any ‘hot spots’ in the liquid that could potentially damage items.

- High-Grade Stainless steel constructionLow consumption of cleaning detergents.

- Bespoke to individual customer requirements.

Specs:

- Micro Computer Controlled Ultrasonic Generators: Provides a fast & gentle cleaning.

- PLC touch screen controls: Easy to operate with clear instructions.

- Frequency sweep circuit: Eliminates ‘hot spots’ in the solution to avoid roller damage.

- 24/7 Heater control: Set the heating to come on whenever you want so the tank is ready when you want.

- Low water level lockout: Stops the machine from overheating when the tank is empty to reduce operator error.

- PLC driven fault-finding diagnostics: Identifies any problems should they arise.

- Bi-direction roller rotation: Provides an even clean with little input from the operator, prevents roller creeping or staying in one position.

- Multi-lingual instruction facility – Touch screen instructions & commands in the language of your choice.

Our tanks offer an outstanding clean for anilox rollers without the need to remove gears or bearings and giving a high level of anilox sealant care.

Applications:

For cleaning laser-engraved ceramic and chrome-plated Anilox rollers and sleeves.Suitable for water-based, solvent-based and UV inks and coatings.

Warranty:

All Camsonic models have a 2-year warranty on all parts.

| Title | Narrow Web Ultrasonic Anilox Roller Cleaning System Princess | |

| Collection | Anilox Cleaning Machines | |

| Made In | United Kingdom | |

| Is Bespoke? | Yes | |

| Has Warranty? | Yes | |

| Finance Available? | Yes | |

You Might Also Be Interested In