Medium Web Ultrasonic Anilox Roller Cleaning, Anilox Cleaning Solutions

Collection: Anilox Cleaning Machines

Medium Web Ultrasonic Anilox Roller Cleaning, Anilox Cleaning Solutions

Collection: Anilox Cleaning Machines

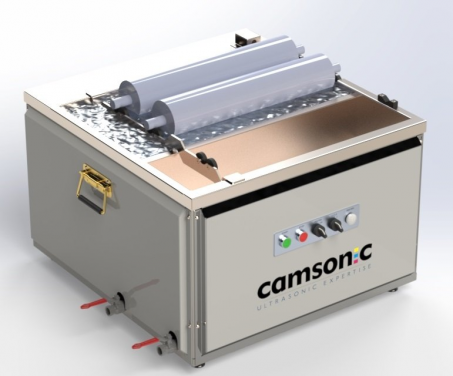

Floor Standing ultrasonic anilox cleaning machine obtainable in two anilox cleaning solutions sizes 1500 and 2000, Will clean rollers with face lengths of up to 2000mm and diameters of 200mm.

OPTIONS

Optional Extras:

- Auto dosing pump for detergent.

- Remote Access for fault finding.

- Diaphragm DrainPump for Emptying the machine

Features:

- Micro Computer Controlled Ultrasonic Generators: Provides a fast & gentle cleaning.

- PLC touch screen controls: Easy to operate with clear instructions.

- Frequency sweep circuit: Eliminates ‘hot spots’ in the solution to avoid roller damage.

- 24/7 Heater control: Set the heating to come on whenever you want so the tank is ready when you want.

- Low water level lockout: Stops the machine from overheating when the tank is empty to reduce operator error.

- PLC driven fault-finding diagnostics: Identifies any problems should they arise.

- Bi-direction roller rotation: Provides an even clean with little input from the operator, prevents roller creeping or staying in one position.

- Multi-lingual instruction facility – Touch screen instructions & commands in the language of your choice.

Our tanks offer an outstanding clean for anilox rollers without the need to remove gears or bearings and giving a high level of anilox sealant care.

There are four machines offered in this range:

One Roller: This machine can only wash one roller at a time. A single roller rinse tank supplied as standard.

Two Roller: This machine can wash two rollers simultaneously. A single roller rinse tank supplied as standard.

Three Roller: This machine can wash three rollers simultaneously. A single roller rinse tank supplied as standard.

Four Roller: This machine can wash four rollers simultaneously. A single roller rinse tank supplied as standard.

2000 WILL CLEAN ROLLERS WITH FACE LENGTHS OF UP TO 2000MM AND DIAMETERS OF 200MM.

There are four machines offered in this range:

One Roller: This machine can only wash one roller at a time. A single roller rinse tank supplied as standard.

Two Roller: This machine can wash two rollers simultaneously. A single roller rinse tank supplied as standard.

Three Roller: This machine can wash three rollers simultaneously. A single roller rinse tank supplied as standard.

Four Roller: This machine can wash four rollers simultaneously. A single roller rinse tank supplied as standard.

- All units include automatic filtration as standard.

- All units include a hinged lid as standard.

- Adjustable roller supports supplied as standard.

- Fast and easy to operate with touch screen controls simplifies multi-stage operation to one press of a button.

- Designed to clean your items with minimal input from the operator.

- Frequency sweep circuit which automatically changes the frequency to reduce the chance of any ‘hot spots’ in the liquid that could potentially damage items.

- High-Grade Stainless steel construction.

- Low consumption of cleaning detergents.

- Bespoke to individual customer requirements.

Applications:

For cleaning laser-engraved ceramic and chrome-plated Anilox rollers and sleeves.Suitable for water-based, solvent-based and UV inks and coatings.

Warranty:

All Camsonic models have a 2-year warranty on all parts.

Floor Standing ultrasonic anilox cleaning machine obtainable in two anilox cleaning solutions sizes 1500 and 2000, Will clean rollers with face lengths of up to 2000mm and diameters of 200mm.

OPTIONS

Optional Extras:

- Auto dosing pump for detergent.

- Remote Access for fault finding.

- Diaphragm DrainPump for Emptying the machine

Features:

- Micro Computer Controlled Ultrasonic Generators: Provides a fast & gentle cleaning.

- PLC touch screen controls: Easy to operate with clear instructions.

- Frequency sweep circuit: Eliminates ‘hot spots’ in the solution to avoid roller damage.

- 24/7 Heater control: Set the heating to come on whenever you want so the tank is ready when you want.

- Low water level lockout: Stops the machine from overheating when the tank is empty to reduce operator error.

- PLC driven fault-finding diagnostics: Identifies any problems should they arise.

- Bi-direction roller rotation: Provides an even clean with little input from the operator, prevents roller creeping or staying in one position.

- Multi-lingual instruction facility – Touch screen instructions & commands in the language of your choice.

Our tanks offer an outstanding clean for anilox rollers without the need to remove gears or bearings and giving a high level of anilox sealant care.

There are four machines offered in this range:

One Roller: This machine can only wash one roller at a time. A single roller rinse tank supplied as standard.

Two Roller: This machine can wash two rollers simultaneously. A single roller rinse tank supplied as standard.

Three Roller: This machine can wash three rollers simultaneously. A single roller rinse tank supplied as standard.

Four Roller: This machine can wash four rollers simultaneously. A single roller rinse tank supplied as standard.

2000 WILL CLEAN ROLLERS WITH FACE LENGTHS OF UP TO 2000MM AND DIAMETERS OF 200MM.

There are four machines offered in this range:

One Roller: This machine can only wash one roller at a time. A single roller rinse tank supplied as standard.

Two Roller: This machine can wash two rollers simultaneously. A single roller rinse tank supplied as standard.

Three Roller: This machine can wash three rollers simultaneously. A single roller rinse tank supplied as standard.

Four Roller: This machine can wash four rollers simultaneously. A single roller rinse tank supplied as standard.

- All units include automatic filtration as standard.

- All units include a hinged lid as standard.

- Adjustable roller supports supplied as standard.

- Fast and easy to operate with touch screen controls simplifies multi-stage operation to one press of a button.

- Designed to clean your items with minimal input from the operator.

- Frequency sweep circuit which automatically changes the frequency to reduce the chance of any ‘hot spots’ in the liquid that could potentially damage items.

- High-Grade Stainless steel construction.

- Low consumption of cleaning detergents.

- Bespoke to individual customer requirements.

Applications:

For cleaning laser-engraved ceramic and chrome-plated Anilox rollers and sleeves.Suitable for water-based, solvent-based and UV inks and coatings.

Warranty:

All Camsonic models have a 2-year warranty on all parts.

| Title | Medium Web Ultrasonic Anilox Roller Cleaning, Anilox Cleaning Solutions | |

| Collection | Anilox Cleaning Machines | |

| Made In | United Kingdom | |

| Is Bespoke? | Yes | |

| Has Warranty? | Yes | |

| Finance Available? | Yes | |

You Might Also Be Interested In