Industrial Heavy Duty Ultrasonic Anilox Cleaning Machine - Automatic

Collection: Anilox Cleaning Machines

Industrial Heavy Duty Ultrasonic Anilox Cleaning Machine - Automatic

Collection: Anilox Cleaning Machines

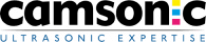

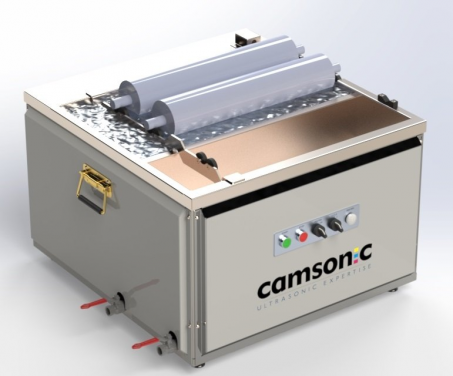

CamsonicLtd has produced yet another stunning automatic machine for cleaning large and heavy rollers. This machine is destined for a major German corrugated printer.

OPTIONS

The operator needs to set three parameters. The wash, rinse and drying phase time in minutes or leave them at the factory default settings.

The lid should be opened, and a dirty roller is loaded.

After closing the cover, the green cycle start button should be pressed. This will commence the cleaning cycle, and the software will implement the following actions.

The rotating system and the transfer pump are immediately enabled so the roller will start to rotate and solution transferred from the holding tank into the ultrasonic tank. The green indicating light mounted on the top of the control panel would be on continuous. When the solution in the ultrasonic tank reaches the operational level, the transfer pump is disabled.

The software will perform the next phase, which is to remove air from the solution in the ultrasonic tank; this is known as degassing.

After the degassing phase completed, the ultrasonic wash phase will commence and continue for the duration of the set time. During this phase ultrasound would be produced to help remove ink from the roller which will continue to rotate until the end of the cleaning cycle.

On completion of the wash phase, the software will enable the drain pump, and the cleaning solution will be transferred back into the holding tank.

When the ultrasonic tank is completely empty, the rinse phase would commence and continue for the duration of the set time. During this phase of the cleaning cycle, the rinse drain valve would open and remain open until the end of the cleaning cycle. The rinse solenoid valve which is connected to mains water, would also open, and cold water would be sprayed onto the rotating roller through dedicated jets.

On completion of the rinse phase, the rinse solenoid valve would close, and the drying phase would commence. In this phase, the drying solenoid valve which is connected to compressed air would open, and compressed air would be blown onto the still rotating roller for the time selected. After the duration of this phase, the green indicating light mounted on top of the control panel would flash to alert the operator that the cleaning cycle is over. The lid should now be opened and the clean roller removed.

CamsonicLtd has produced yet another stunning automatic machine for cleaning large and heavy rollers. This machine is destined for a major German corrugated printer.The unit is from our range of machines known as Big Mach. This machine is controlled from an easy to use touch screen mounted on the control panel. The touch screen is operated in two languages English and of course German.Camsonic client brief was to produce a machine that would wash, rinse and dry heavy rollers with the minimum amount of input from the operator. The system consists of two stainless steel tanks, a holding tank and the ultrasonic wash tank. The cleaning solution stored in the holding tank is maintained at40C ready to be transferred into the ultrasonic tank as required.

CamsonicLtd has produced yet another stunning automatic machine for cleaning large and heavy rollers. This machine is destined for a major German corrugated printer.

OPTIONS

The operator needs to set three parameters. The wash, rinse and drying phase time in minutes or leave them at the factory default settings.

The lid should be opened, and a dirty roller is loaded.

After closing the cover, the green cycle start button should be pressed. This will commence the cleaning cycle, and the software will implement the following actions.

The rotating system and the transfer pump are immediately enabled so the roller will start to rotate and solution transferred from the holding tank into the ultrasonic tank. The green indicating light mounted on the top of the control panel would be on continuous. When the solution in the ultrasonic tank reaches the operational level, the transfer pump is disabled.

The software will perform the next phase, which is to remove air from the solution in the ultrasonic tank; this is known as degassing.

After the degassing phase completed, the ultrasonic wash phase will commence and continue for the duration of the set time. During this phase ultrasound would be produced to help remove ink from the roller which will continue to rotate until the end of the cleaning cycle.

On completion of the wash phase, the software will enable the drain pump, and the cleaning solution will be transferred back into the holding tank.

When the ultrasonic tank is completely empty, the rinse phase would commence and continue for the duration of the set time. During this phase of the cleaning cycle, the rinse drain valve would open and remain open until the end of the cleaning cycle. The rinse solenoid valve which is connected to mains water, would also open, and cold water would be sprayed onto the rotating roller through dedicated jets.

On completion of the rinse phase, the rinse solenoid valve would close, and the drying phase would commence. In this phase, the drying solenoid valve which is connected to compressed air would open, and compressed air would be blown onto the still rotating roller for the time selected. After the duration of this phase, the green indicating light mounted on top of the control panel would flash to alert the operator that the cleaning cycle is over. The lid should now be opened and the clean roller removed.

CamsonicLtd has produced yet another stunning automatic machine for cleaning large and heavy rollers. This machine is destined for a major German corrugated printer.The unit is from our range of machines known as Big Mach. This machine is controlled from an easy to use touch screen mounted on the control panel. The touch screen is operated in two languages English and of course German.Camsonic client brief was to produce a machine that would wash, rinse and dry heavy rollers with the minimum amount of input from the operator. The system consists of two stainless steel tanks, a holding tank and the ultrasonic wash tank. The cleaning solution stored in the holding tank is maintained at40C ready to be transferred into the ultrasonic tank as required.

| Title | Industrial Heavy Duty Ultrasonic Anilox Cleaning Machine - Automatic | |

| Collection | Anilox Cleaning Machines | |

| Made In | United Kingdom | |

| Is Bespoke? | Yes | |

| Has Warranty? | Yes | |

| Finance Available? | Yes | |

You Might Also Be Interested In