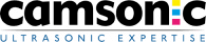

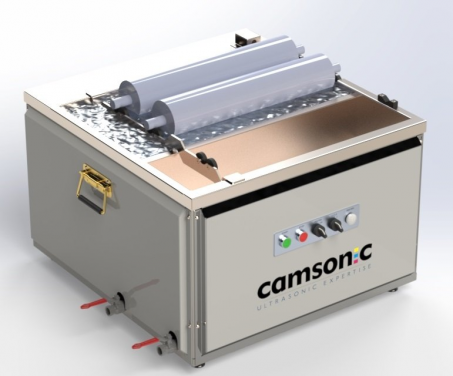

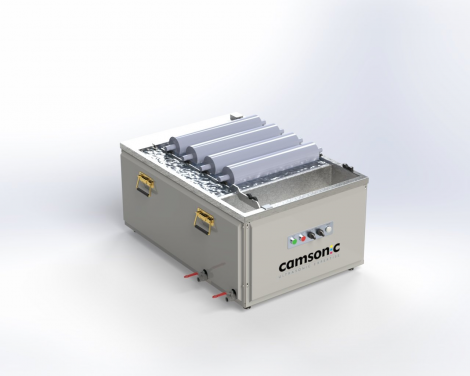

Bench Top Ultrasonic Anilox Roller Cleaner Little Mach

Collection: Anilox Cleaning Machines

Bench Top Ultrasonic Anilox Roller Cleaner Little Mach

Collection: Anilox Cleaning Machines

Anilox cleaning solutions Camsonic manufacture two sizes of machines in this range, The 400 also 600 series.

OPTIONS

- No need to remove bearings and gears before cleaning.

- Adjustable roller supports supplied as standard.

- PLC controlled.

- Pushbuttons and Selector switches for easy control.

- 2 Wash Cycle Time available.

- Type K thermocouple temperature control.

- Designed to clean your rollers with minimal input from the operator.

- Frequency sweep circuit which automatically changes the frequency to reduce the chance of any ‘hot spots’ in the liquid that could potentially damage items.

- Constructed from stainless steel 316.

- Low consumption of cleaning detergents.

Specs:

- Micro Computer Controlled Ultrasonic Generators: Provides a fast & gentle cleaning.

- Frequency sweep circuit: Eliminates ‘hot spots’ in the solution to avoid roller damage.

- Low water level lockout: Stops the machine from overheating when the tank is empty to reduce operator error.

- There is a 2 and 4 bespoke roller unit available in each series.

- There is no need to remove gears or bearings before cleaning.

- Each machine supplied complete with a rinse tank.

- Each machine is available in our standard or advance option.

- The cleaning results are the same for both options; however, there are more features available in the advance option.

- The 400 series will clean rollers with face lengths up to 400 mm.

- The 600 series will clean rollers with face lengths up to 600 mm.

- Each machine will clean rollers with diameters up to 100 mm.

Applications:

For cleaning laser-engraved ceramic and chrome-plated Anilox rollers, anilox cleaning solutions

and sleeves. Suitable for water-based, solvent-based and UV inks and coatings.

Warranty:

All Camsonic models have a 2-year warranty on all parts.

Anilox cleaning solutions Camsonic manufacture two sizes of machines in this range, The 400 also 600 series.

OPTIONS

- No need to remove bearings and gears before cleaning.

- Adjustable roller supports supplied as standard.

- PLC controlled.

- Pushbuttons and Selector switches for easy control.

- 2 Wash Cycle Time available.

- Type K thermocouple temperature control.

- Designed to clean your rollers with minimal input from the operator.

- Frequency sweep circuit which automatically changes the frequency to reduce the chance of any ‘hot spots’ in the liquid that could potentially damage items.

- Constructed from stainless steel 316.

- Low consumption of cleaning detergents.

Specs:

- Micro Computer Controlled Ultrasonic Generators: Provides a fast & gentle cleaning.

- Frequency sweep circuit: Eliminates ‘hot spots’ in the solution to avoid roller damage.

- Low water level lockout: Stops the machine from overheating when the tank is empty to reduce operator error.

- There is a 2 and 4 bespoke roller unit available in each series.

- There is no need to remove gears or bearings before cleaning.

- Each machine supplied complete with a rinse tank.

- Each machine is available in our standard or advance option.

- The cleaning results are the same for both options; however, there are more features available in the advance option.

- The 400 series will clean rollers with face lengths up to 400 mm.

- The 600 series will clean rollers with face lengths up to 600 mm.

- Each machine will clean rollers with diameters up to 100 mm.

Applications:

For cleaning laser-engraved ceramic and chrome-plated Anilox rollers, anilox cleaning solutions

and sleeves. Suitable for water-based, solvent-based and UV inks and coatings.

Warranty:

All Camsonic models have a 2-year warranty on all parts.

| Title | Bench Top Ultrasonic Anilox Roller Cleaner Little Mach | |

| Collection | Anilox Cleaning Machines | |

| Made In | United Kingdom | |

| Is Bespoke? | Yes | |

| Has Warranty? | Yes | |

| Finance Available? | Yes | |

You Might Also Be Interested In